|OUR SERVICE

1. Raw Material Sourcing

1. Raw Material Sourcing

Whether you need materials for a single project or ongoing production, our raw material sourcing capabilities include:

- High-Quality Materials: Providing top-grade raw materials to ensure the durability and reliability of your products.

- Wide Range of Options: Offering a diverse selection of materials to meet various industry needs.

- Global Sourcing: Leveraging a global network of suppliers to secure the best materials at competitive prices.

- Reliable Supply Chain: Ensuring a consistent and dependable supply of materials to keep your operations running smoothly.

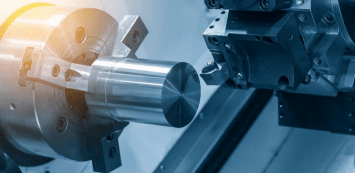

2. Turning Services

2. Turning Services

Whether it’s for small-scale prototypes or large production runs, our turning capabilities include:

- High Precision Turning: Achieving tight tolerances and smooth finishes for critical applications.

- Complex Geometry: Creating intricate shapes and profiles that meet specific design requirements.

- Customization: Tailoring parts to exact specifications for unique applications.

- Efficient Production: Ensuring quick turnaround times without compromising on quality.

3. Milling Services

3. Milling Services

Our state-of-the-art CNC milling machines are equipped to handle intricate designs and high volume production with the following features:

- 3-Axis, 4-Axis, and 5-Axis Milling: Offering flexibility and precision for complex part geometries.

- Surface Finishing: Providing high-quality surface finishes that meet stringent industry standards.

- Material Versatility: Working with a broad range of materials from aluminum and steel to titanium and engineered plastics.

- Prototyping and Production: Supporting both rapid prototyping and full-scale production to meet your project needs.

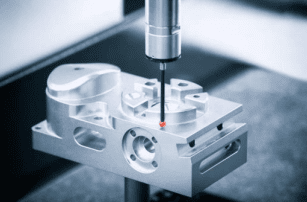

4. Quality Assurance

4. Quality Assurance

At AAKAAR PRECITECH, quality is paramount. Our machining services are backed by a robust quality control system that includes:

- In-process Inspection: Continuous monitoring and measurement during the machining process to ensure accuracy.

- Final Inspection: Comprehensive checks of all dimensions and tolerances before delivery.

- Advanced Metrology Equipment: Utilizing the latest measurement tools and technologies to verify precision.

|OUR MACHINE CAPABILITIES

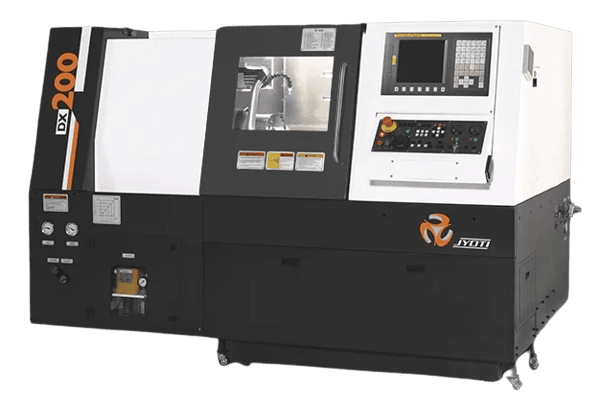

|Turning Centers

JYOTI DX 200 5A - 01 NO.

- Max. Turning Dia: 365 mm;

- Max. Turning Length: 500 mm;

- X-Axis Travel (Cross): 200 mm;

- Z Axis Travel (Longitudinal): 500 mm

JYOTI DX 200 3B - 01 No.

JYOTI DX 200 3B - 01 No.

- Max. Turning Dia: 320 mm;

- Max. Turning Length: 300 mm;

- X-Axis Travel (Cross): 175 mm;

- Z Axis Travel (Longitudinal): 300 mm

Ace Super Jobber 500 LM - 02 No.s

- Maximum turning Ø 350 mm;

- Maximum turning length 500mm

- Linear motion guide-ways

|Vertical Milling Center

Maple MA850 - 01 No.

Maple MA850 - 01 No.

- Work Table Max Weight 600 kgs

- X-Axis Travel 800 mm

- Y-Axis Travel 520 mm

- Z-Axis Travel 550 mm